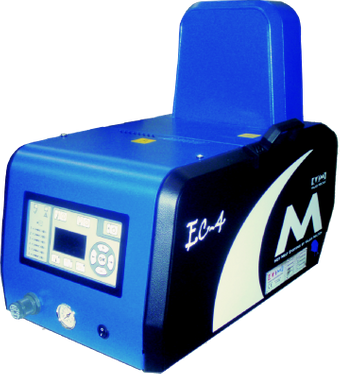

EC Series Hot Melt Units

The ApplicationThe Evolution C Series technology is the newest innovation for hot melt adhesive melters. The design is a culmination of features that were specifically crafted to meet the most current needs communicated by hot melt unit users worldwide. A new user-friendly control panel supports a quick and easy configuration to adapt to any work requirement. Valco Melton's new EC Series hot melt adhesive unit offers optimum reliability and total control of the unit's operation. Supported by the most current features and technology, the Valco Melton EC series unit easily takes recognition as the best in its class in performance. Competitive AnalysisThe EC series tanks are comparable and compatible with the Nordson 2300, 3000, MESA, and Problue series. All hoses, guns, pumps, filters are interchangeable. The EC series can be used in place of the Nordson Problue units. Adhesive RequirementsEVA packaging adhesives and PSA pressure sensitive adhesives.

|

|

While not listed is also available in 30 (EC 30) and 50 (EC 50) kgs. | |||

| Unit | EC 4 | EC 8 | EC 14 | |

| Tank Capacity | 4L | 8L | 14L | |

| Melting Capacity (kg/h) | 4,2 | 7,9 | 13,5 | |

| Pump Compression Ratio | 1:14 | 1:14 - 1:13 | 1:13 | |

| Max Pump Capacity (kg/h) | 35kg (77.2lb) | 35-100kg (77.2-220.5lb) | 100kg (220.5lb) | |

| Working temperature range | 30 - 240°C (86 - 464°F) | |||

| Electrical connection | 220 I + T, 220III + T, 380III + N + T | |||

| Working viscosity | 50,000cps | |||

| Air pressure | 0.5 - 6bar (7.25 - 87psi) | |||

| Electrical consumption | 1800w | 2800w | 4000w | |

| Max channel power (W) | 1-2 exits | 3,4,5,6 exits | ||

| Total channel (hose + gun) | 2300W | 1450W | ||

| Per exit (hose and gun) | 2300W | 1450W | ||

| Per channel (hose or gun) | 2300W | 1450W | ||

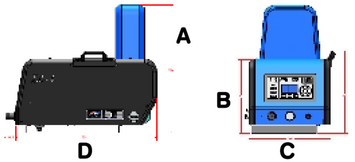

| Dimensions | EC 4 | EC 8 | EC 14 | |

|

A | 532mm (21") | 532mm (21") | 592mm (23.3") |

| B | 307mm (12.1") | 307mm (12.1") | 367mm (14.4") | |

| C | 340mm (13.4") | 340mm (13.4") | 340mm (13.4") | |

| D | 583mm (23") | 658mm (26") | 658mm (26") |

|

EC Series Hot Melt Unit Brochure |